Autoclaved Aerated Concrete (AAC) is a lightweight, soundproof, thermally insulated, and environmentally friendly construction material suitable for residential and industrial projects.

In today’s construction landscape, the demand for sustainable and eco-friendly materials is rapidly increasing. AAC meets all of these criteria with its advantages: lightweight properties, excellent thermal and sound insulation, and minimal environmental impact. In this article, we will explore what AAC is, its core benefits, and why it should be considered for your building projects.

1. What is AAC?

AAC, or Autoclaved Aerated Concrete, is an ultra-lightweight, non-fired building material made from raw materials like sand, cement, lime, gypsum, aluminum powder, and water. These are mixed in precise proportions and processed using autoclaving technology.

Invented by Swedish architect Johan Eriksson in the 1920s, AAC offers unique characteristics such as ultra-lightweight structure, thermal and acoustic insulation, and outstanding fire resistance.

2. How is AAC Produced?

AAC is available in two main forms:

- AAC EBLOCK Bricks

- ALC EPANEL Panels

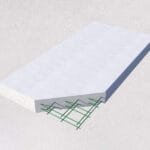

Though their production processes are similar, the key difference lies in the addition of a steel mesh when manufacturing EPANEL panels.

2.1 AAC Brick Production Process

Step 1: Raw Material Preparation

All input materials are carefully selected from reputable suppliers. Key ingredients include cement, lime, sand, gypsum, and water.

Step 2: Raw Material Processing

Lime and sand are finely ground; other materials are received in powder form and proportioned appropriately.

Step 3: Mixing

A computer controls moisture and temperature in the mixing chamber. Each ingredient is added in precise order and amounts to form a homogeneous mixture.

Step 4: Pouring into Molds

The mixture is poured into molds automatically with exact quantities.

Step 5: Pre-Curing

Molds are moved to a curing chamber, kept at 40-50°C. A chemical reaction occurs between calcium hydroxide and aluminum powder, creating millions of tiny air bubbles.

Step 6: Cutting

After curing, the hardened mixture (now a soft cake) is cut into desired sizes.

Step 7: Autoclaving

Cut blocks are placed into an autoclave chamber for 10-11 hours to achieve optimal strength.

Step 8: Packaging

Once autoclaving is complete, the AAC blocks are classified and packaged.

2.2 EPANEL Panel Production

The panel production process follows the same steps as above, with one distinction: in Step 4, a pre-treated, welded anti-rust steel mesh is placed into the mold before pouring the AAC mixture.

3. Key Advantages of AAC

- Lightweight: One-third the weight of clay bricks and one-fourth that of traditional concrete.

- Fire Resistant: Withstands temperatures up to 1200°C and provides fire safety for up to 4 hours.

- Thermal Insulation: Low thermal conductivity ensures cooler summers and warmer winters, reducing energy usage by up to 40%.

- Acoustic Insulation: Offers double the soundproofing of conventional bricks.

- High Durability: Autoclaving stabilizes chemical and crystal structure, primarily forming robust tobermorite minerals.

- Eco-Friendly: Reduces CO2 emissions by up to 5 times during raw material processing and waste treatment.

- Dimensional Precision: Large block sizes ensure high precision in wall alignment and minimize plastering material waste.

4. Applications of AAC

From residential to commercial and industrial buildings, lightweight AAC bricks and ALC panels offer spatial and structural benefits aligned with modern construction trends.

Residential Projects

- Houses: Villas, townhouses, and steel-frame homes use AAC bricks for exterior and partition walls, and EPANEL panels for roofs and floors.

- Swiftlet Farms: Thermal properties of AAC help maintain ideal conditions for swiftlets to nest and thrive.

Commercial Projects

- Offices and Shopping Malls: AAC enhances energy efficiency and noise reduction for better work and customer environments.

- High-Rise Apartments: Non-fired AAC bricks provide up to 4-hour fire resistance, ensuring residential safety.

Industrial Facilities

- Factories and Warehouses: EPANEL panels with large sizes enable fast installation and provide fire protection for storage and production areas.

Public Infrastructure

- Schools, Hospitals, Public Buildings: Widely adopted per Circular No. 13/2017/TT-BXD, which mandates non-fired materials in construction.

5. Quality Standards of AAC

EBLOCK AAC bricks and EPANEL panels are produced using modern equipment and undergo strict quality control in compliance with:

- ISO 9001:2015

- VGBC Member Certificate

- TCVN 7959:2017

- QCVN 06:2022/BXD fire resistance standards

6. AAC Installation Process

- Site Preparation: Clean and level the foundation to ensure structural integrity.

- Special Mortar Mixing: Use specialized mortar with strong adhesion properties for AAC bricks.

- Placing First Course: Begin with a corner block aligned to the wall layout.

- Subsequent Courses: Apply mortar evenly to bond bricks tightly.

- Finishing: Sand the surface with abrasive tools, skim with thin plaster, and paint as needed.

7. Comparing AAC with Traditional Materials

AAC has emerged as a strong alternative to traditional fired clay bricks, eliminating their major disadvantages.

Size

AAC bricks (600×200×100mm) are 8x larger than clay bricks (180×80×80mm), making transport and construction faster and more efficient.

Density

AAC (451-550 kg/m3, 3.5 MPa) is 3x lighter than clay bricks (1,800 kg/m3), reducing structural load and foundation costs.

Construction Time

Thanks to its size and weight, AAC allows for construction at twice the speed of clay bricks, reducing labor costs and often exceeding project deadlines.

Thermal Insulation

AAC’s internal air bubbles provide better insulation than traditional bricks, cutting energy costs and improving comfort.

For a detailed comparison between AAC, Tuynel bricks, and cement-based materials, see our article: Comparing 3 Common Wall Systems: AAC EBlock – Tuynel – Cement Blocks.

EBLOCK Factory: One of Southeast Asia’s most advanced AAC facilities, covering 50,000 m² with an annual capacity of 400,000 m³.

In Vietnam, New Era Home JSC proudly pioneers in producing AAC EBLOCK bricks and EPANEL lightweight concrete panels. With over 15 years in the building materials industry and a 5-hectare factory, we are committed to delivering sustainable, high-quality, and safe products.

For product inquiries, please contact your nearest distributor or agent of New Era Home JSC for tailored solutions and competitive pricing.

EBLOCK – A Brand by NEW ERA HOME

Contact Us:

- ☎ (+84) 28 3526 7177

- ✉️ eblock@newerahome.vn

- 🏢 60 Dang Dung Street, Tan Dinh Ward, District 1, Ho Chi Minh City, Vietnam