AAC EBLOCK autoclaved aerated concrete bricks are green building materials that are ultra-lightweight and thermally efficient. Discover their advantages, dimensions, and applications below.

The construction industry today faces increasing challenges such as environmental regulations, rising costs, and the demand for sustainable, energy-saving materials. Traditional building materials often fall short of these standards. The introduction of AAC bricks has sparked a green revolution in the construction materials sector. Lightweight concrete bricks offer superior durability, thermal insulation, and environmental friendliness. Read on to learn more about this innovative product.

1. What Are AAC Bricks?

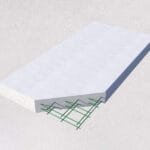

AAC (Autoclaved Aerated Concrete) EBLOCK bricks are products manufactured using AAC materials (see our previous article for a full explanation). These bricks retain all the benefits of AAC, such as ultra-light weight, fire resistance, soundproofing, and thermal insulation. EBLOCK AAC bricks are produced to standard sizes and specifications.

AAC bricks are widely used in construction worldwide—making up over 70% of total brick usage in some countries. In Vietnam, the government has issued regulations encouraging the use of non-fired materials like AAC bricks and EPANEL panels in civil and industrial construction, helping raise awareness of and commitment to environmental protection.

See: Circular on the Use of Non-Fired Building Materials in Construction

2. Key Benefits of AAC Bricks

2.1 Ultra-Lightweight

AAC bricks weigh only one-third of fired clay bricks and one-fourth of conventional concrete bricks. This significantly reduces costs for structural frames, foundations, and transportation.

2.2 Exceptional Fire Resistance

Made from inorganic materials, AAC bricks can resist fire for up to 4 hours—meeting stringent fire safety standards per QCVN 06:2022/BXD. Ideal for high-rise buildings, warehouses, and factories.

2.3 Excellent Sound Insulation

Thanks to their air bubble structure, AAC bricks naturally absorb and diffuse sound—ideal for buildings requiring high acoustic performance such as hotels, offices, schools, and hospitals.

2.4 Superior Thermal Insulation

With extremely low thermal conductivity, AAC bricks deliver the “Warm in Winter, Cool in Summer” effect. They meet QCVN 09:2017/BXD standards for energy-efficient buildings, significantly reducing electricity consumption.

2.5 High Durability

AAC is a type of concrete cured with saturated steam under high pressure and temperature, resulting in uniformity and a robust crystalline structure.

2.6 Green Material

EBLOCK AAC bricks are environmentally friendly and human-safe. They’ve received numerous prestigious green certifications both locally and internationally and are recommended by the Vietnam Green Building Council.

2.7 High Dimensional Accuracy

With minimal size deviation (±2mm), AAC bricks are larger and more precise than conventional bricks, reducing plaster usage and finishing time.

3. Applications of AAC Bricks

3.1 Exterior Walls

Exterior walls provide protection against harsh environmental conditions (storms, rain, wind). AAC bricks offer flexibility in wall thickness and prevent cracking under adverse weather while keeping homes thermally balanced.

3.2 Partition Walls

AAC bricks, composed of 80% micro air bubbles, offer excellent sound insulation—ideal for partitioning living spaces and blocking external noise.

3.3 Fire-Resistant Walls

AAC is an inorganic, non-flammable material with a 4-hour fire rating, complying with QCVN 06:2022/BXD fire safety standards. Common in high-rises, factories, and warehouses.

3.4 Fence Construction

AAC EBLOCK fences are quick to build, saving labor and time. Their smooth, gray-white finish requires no plastering and adds fire and sound resistance—ideal for transformer stations and industrial facilities.

3.5 Floor Elevation

To remedy subsidence issues, AAC bricks are often used to elevate floor levels efficiently and cost-effectively. Their light weight reduces structural load while allowing ideal height adjustments.

4. Notable Projects Using AAC Bricks

EBLOCK AAC bricks are used in many large-scale domestic and international projects, offering cost-effective and environmentally friendly building solutions.

International Projects

- Yang City Building (Taiwan): AAC used for exterior and interior walls

- Quan Min Wan Sui Building (Taiwan): Extensive AAC application throughout the structure

Vietnamese Projects

- Empire City Thủ Thiêm: AAC bricks used in partition walls of this premium commercial–residential complex

- The Habitat Bình Dương: AAC bricks create international-standard living environments

- Newtecons Tower: AAC supplied by EBLOCK for the investor’s headquarters

- University of Banking (Thủ Đức Campus)

5. Sizes and Specifications of AAC Bricks

AAC bricks are manufactured to standard dimensions (600x200x100mm) but can be customized. Below are common specifications and compressive strengths based on TCVN 7959:2017.

| Specification | EBLOCK 3.5 | EBLOCK 5.0 | EBLOCK 7.5 |

|---|---|---|---|

| Min. compressive strength (MPa) | 3.5 | 5.0 | 7.5 |

| Equivalent grade (TCVN 7959:2017) | B3 | B4 | B6 |

| Dry density (kg/m³) | 451–550 | 551–650 | 651–750 |

| Dry shrinkage (mm/m) | ≤ 0.2 | ≤ 0.2 | ≤ 0.2 |

| Fire resistance (hours) | >4 | >4 | >4 |

| Sound insulation (dB) | 38 | 45 | 48 |

| Size deviation (mm) | ±2 | ±2 | ±2 |

Available Sizes and Applications

| Length (mm) | Height (mm) | Thickness (mm) | Application |

| 600 | 200/300/400 | 50 | Thermal/cladding protection |

| 600 | 200/300/400 | 75 | Partitions, thermal cladding |

| 600 | 200/300/400 | 100 | Partitions |

| 600 | 200/300/400 | 150 | Partitions or exterior walls |

| 600 | 200/300/400 | 200 | Exterior walls |

| 600 | 200/300/400 | 250 | Special structures |

Custom sizes available upon request.

6. Comparison with Other Brick Types

| Criteria | AAC Bricks | Red Clay Bricks | Cement-Based Bricks |

| Standard Size (mm) | 600x200x100 | 180x80x80 | 200x95x95 |

| Composition | Sand, lime, cement, Al powder | Clay, coal, water | Stone dust, cement, ash |

| Dry Density (kg/m³) | 451–750 | 1500–1800 | 1800–2000 |

| Compressive Strength (MPa) | 3.5–7.5 | 4–12.5 | 5.0–10.0 |

| Thermal Conductivity (W/m·K) | 0.11–0.16 (Excellent) | ~1.15 (Poor) | ~1.3 (Poor) |

| Sound Insulation (dB) | 38–48 (Excellent) | ~28 (Low) | ~30–35 (Average) |

| Fire Resistance (hours) | >4 | 1–2 | >2 |

| Build Speed (m²/day/person) | 30–40 | 8–10 | 12–15 |

| Tech Origin | Germany | Vietnam | Vietnam |

| Mortar Usage (kg/m²) | 8–10 (special mortar) | 20–25 (cement-sand) | 16–20 (cement-sand) |

| Plaster Thickness (mm) | 3–5 (skimcoat) | 15–20 (cement-sand) | 15–20 (cement-sand) |

Note: This comparison is for reference only. Actual results may vary based on wall configuration and thickness.

7. AAC EBLOCK Price List (Reference Only)

| No. | Type & Size (mm) | Compressive Strength (MPa) | Factory Price (VND/m³) |

| 1 | EBLOCK 600x200x100 | 3.5 | 1,687,500 |

| 2 | EBLOCK 600x200x200 | 3.5 | 1,687,500 |

| 3 | EBLOCK 600x200x100 | 5.0 | 1,875,000 |

| 4 | EBLOCK 600x200x200 | 5.0 | 1,875,000 |

For exact pricing and discounts, please contact our nearest distributor or sales representative.

8. Where to Buy AAC Bricks

If you’re looking for AAC materials, New Era Home JSC is a leading manufacturer in Vietnam, with over 15 years of experience. We provide high-quality AAC bricks and EPANEL panels for projects of all sizes.

EBLOCK Factory is located in Thinh Phat Industrial Park, Ben Luc District, Long An Province—50km from Ho Chi Minh City—and is equipped with modern machinery and production lines.

We hope this article has provided a comprehensive overview of AAC bricks. For product inquiries, please call our hotline (+84) 28 3526 7177 or contact your nearest distributor for personalized consultation and quotation.

EBLOCK – A Brand by NEW ERA HOME

Contact Us:

- ☎ (+84) 28 3526 7177

- ✉️ eblock@newerahome.vn

- 🏢 60 Dang Dung Street, Tan Dinh Ward, District 1, Ho Chi Minh City, Vietnam